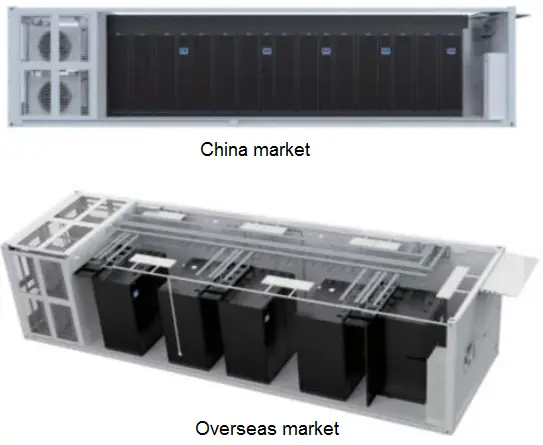

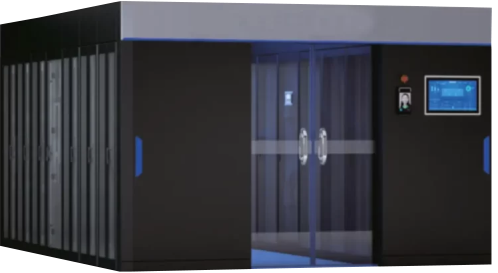

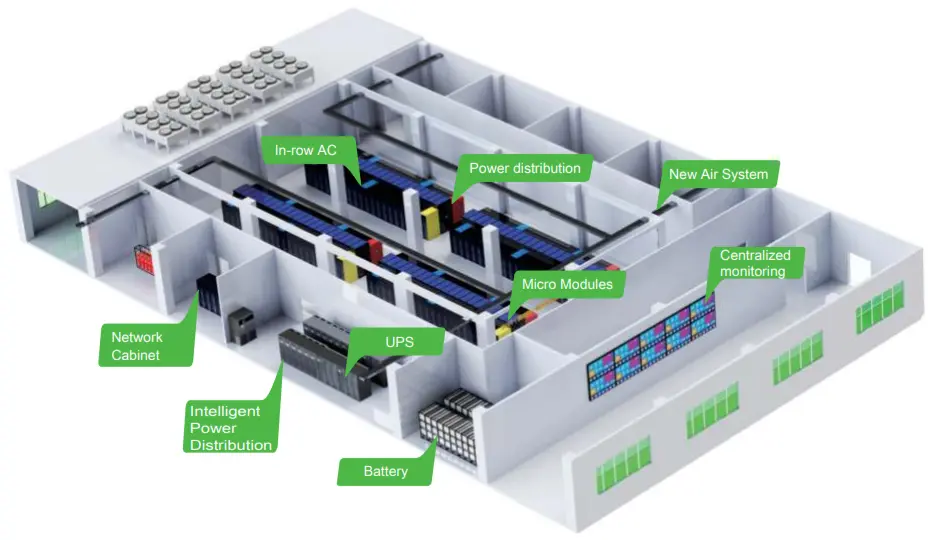

The Protect XL series dual row cabinet data center adopts modular design, integrating power supply and distribution system, air conditioning system, cabinet system, closed aisle system, monitoring system and cabling system into one, and configuring various environmental data sampling sensors for unified monitoring and management by eSite cloud map monitoring system, realizing automatic control and intelligent operation and maintenance, enhancing data center reliability, availability and maintainability.

Integrated Data Center Application Scenario Diagram ∇

Applicable Scene ∇

Large-scale data center, campus data center and other core business server room, suitable for Government, medical, education, finance, telecom and other leasing and self-use businesses.

Applicable power ∇

The maximum supported power of a single cabinet is 10kW per cabinet. And it supports up to 50 cabinet which includes air conditioner and power distribution cabinet.

- All components are manufactured according to international and domestic standards to ensure product quality

- Data center productization, productization reliability up to 99.999%. Adopt integrated design to enhance the overall reliability of the system

- Redundant design of key components to improve system reliability

- The data center power distribution and cooling system is designed according to the international class A server room (international standard Tier Iv level)

- Integrated intelligent monitoring system, early warning of key data to ensure the safety of server room operations reliable

- The average annual PUE can be reduced to 1.30

- The use of in-row air conditioner cooling, closed cooling space to achieve precise cooling near the server side, greatly improving the efficiency of cooling, compared with the traditional server room can save energy by more than 35%; N+X high efficiency online modular UPS with intelligent sleep function to save more energy

- High density deployment, single cabinet up to 10kW

- Integrated power supply and distribution, space saving, 1-2 more equipment cabinets can be deployed

- Remote O&M is unattended, saving TCO

- Standardized components, modular architecture, and rapid ondemand deployment to match your business

- No need for professional machine room, can be installed directly on the concrete floor of the building, reducing the supporting engineering

- The products are standardized, modular, plug-and-play, and easy to install, greatly reducing the installation cycle

- Intelligent and monitoring of the working status of power and environmental systems

- Intelligent lintel, visual display of key information, easy operation and maintenance

- Real-time alerts can be made in time by SMS, telephone, email, sound and light, etc

- Provide a variety of human-machine interaction methods such as operation and maintenance large screen, remote APP, local LCD and remote WEB

- Provide a variety of northbound interfaces such as ModbusTCP, MQTT, etc. for easy system integration

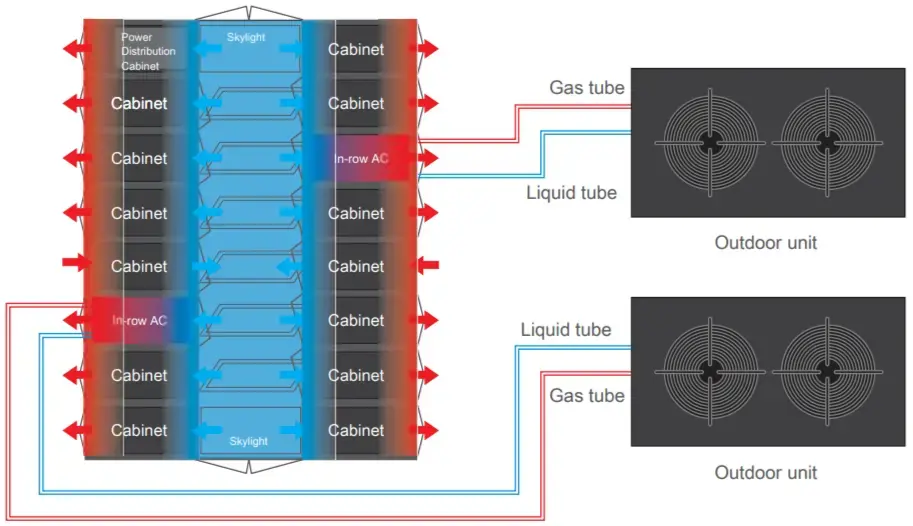

Airflow Reference Chart ∇

Note: When the outdoor unit is higher than the indoor unit: the vertical height difference between indoor and outdoor units should not exceed 20m; when the indoor unit is higher than the outdoor unit: the vertical height difference between indoor and outdoor units should not exceed 5m.

The equivalent length of one way pipeline should not exceed 30m, please contact with professional engineers for more information!

Diversified configurations ∇

Parameters ∇

| iSmart XL Series Dual Row Cabinet Data Center |

|||

| System |

Size(W*D*H) | 3600*L*2600mm(L≤15000mm) | |

| IT rated power/cabinet | 3~10kW | ||

| Door Specifications | Automatic sliding doors/manual sliding doors/pull-out doors | ||

| Intelligent Lighting | LED white light, intelligent color ambient light, linkage with monitoring system. | ||

| Access Control System | Support face/fingerprint/password/IC and other methods can be selected | ||

| Ambient temperature | 0-45℃ | ||

| Ambient Humidity | 10-95%,Relative Humidity | ||

| Protection class | IP20 | ||

| Altitude | 1000 m, more than 1000 m need to be derated. | ||

| Installation method | Direct concrete floor installation / Raised floor installation | ||

| Cabinet |

Dimension (W*D*H) | 600/800*1200*2000mm | |

| Available Space | 42U | ||

| Inlet method | Support up/down wire feed | ||

| Power Supply and Distribution System |

Power Distribution Cabinet |

Input method | Single circuit MCCB/Dual circuit ATS |

| Grid system | 380/400/415Vac,50/60Hz | ||

| Specification | 63~400A | ||

| Lightning Protection |

B/C class optional | ||

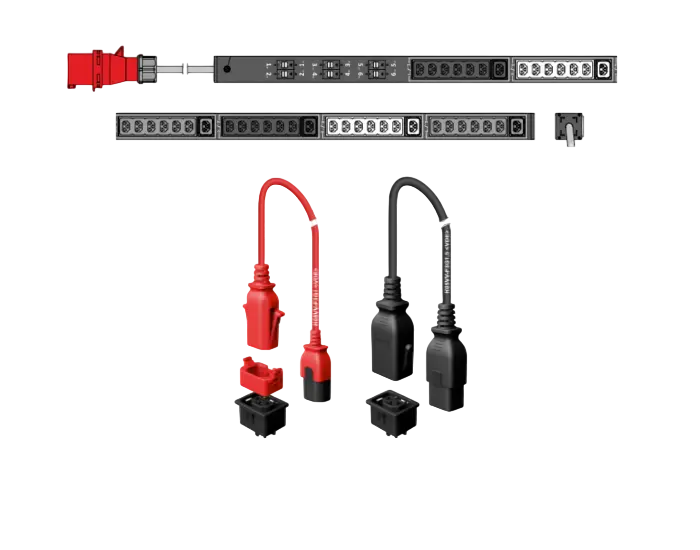

| Type | Integrated UPS distribution cabinet/precision distribution cabinet/intelligent busbar | ||

| UPS | Capacity | Built-in maximum 200kVA, external 200kVA or more | |

| Input Frequency Range |

40-70Hz | ||

| Output PF | 1 | ||

|

Battery

|

Built-in cabinet type battery cabinet or external battery cabinet | ||

| PDU | Ordinary Type | [National standard 12-bit 10A + 3-bit 16A]*2 | |

| Smart Type | 24-port intelligent PDU (optional) | ||

|

Monitoring System

|

HMI | 21.5 inch touch screen | |

| System Functions | Remote WEB/Centralized monitoring of power, environment, video, access control system/Northbound interface | ||

| Monitoring accessories | Smoke sensor/T&H sensor/water flood sensor/infrared sensor/webcam/access control/fire linkage | ||

| Alarm method | E-mail/SMS(optional)/sound and light alarm(optional)/telephone voice(optional)/APP(optional) | ||

| Cooling System |

Air Conditioner Capacity | 12.5~60kW | |

| Cooling method | Air-cooled | ||

| Refrigerant | R410A | ||

Note: The above parameters are for reference, the actual configuration parameters are subject to customer requirements.